- September 17, 2020

- Posted by: Sapience

- Category: Blog

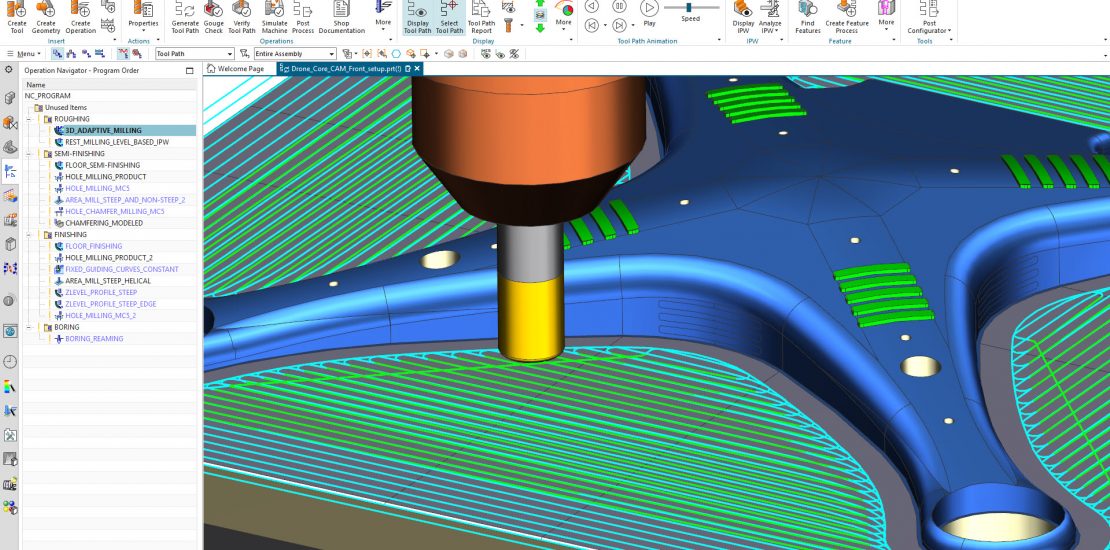

Adaptive Milling, a new technological enhancement provided in NX, is an ideal solution for high speed machining. It is a highly efficient roughing strategy for hard materials at high speeds. In this blog post, we are going to present an overview of Adaptive milling in NX 12.

What is Adaptive Milling?

It is an innovative roughing method, which enables deep cuts and consistent tool load, resulting in high material removal rates. Adaptive milling provides higher productivity and longer tool life as it uses stabilised cutting process. This method ensures consistent and evenly distributed stock on tapered and contoured walls. Hence, it is especially useful on Mold inserts.

What are the benefits of using Adaptive Milling?

- Reduces heat generation

- Reduces vibration in the cutting zone

- Reduces the wear of the cutting tools, extending tool life by 4X

- Reduces machining time by 60% resulting in increased productivity

- Smooth cut patterns optimized for high speed machining

- High Speed Machining (HSM) cutting strategies with smooth flowing toolpath for steep and non-steep regions

What are different types of Adaptive Milling?

- High Feed rate Cutting (HFC) – Small depth of cut, but big stepover, high cutting feed rates

- High Dynamic Cutting (HDC) – Utilizing the complete flute length, but maintaining a consistent chip thickness and high cutting speeds

- High Speed Cutting (HSC) – Small cut depth, but high cutting speeds

- High Performance Cutting (HPC) – Utilizing the complete flute length and a big stepover, while driving with higher cutting speeds than in conventional roughing paths

In next blog post, we will discuss features in NX CAM that are useful in Adaptive milling such as:-

- Bottom Up Cutting

- Minimum Curvature Radius and Cut Depth