- September 21, 2020

- Posted by: Sapience

- Category: Blog

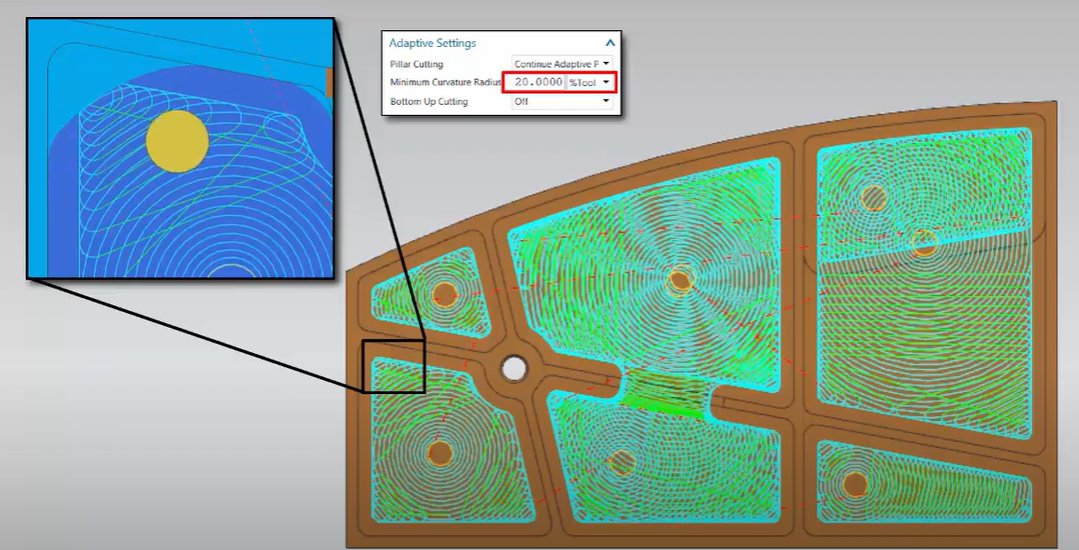

The New minimum curvature radius option in Adaptive milling gives you better cutting control in corners by preventing small cuts which can cause excessive tool wear particularly machining hard materials.

Previously, the minimum curvature radius was set to zero which left no stock in corners and produce many small cuts with small arc lengths. The new minimum curvature radius option is in the adaptive settings section of the cutting parameters dialogue box. Specifying a 20% tool diameter for the minimum curvature radius leaves stock but increases the size of the smallest cuts in the corner.

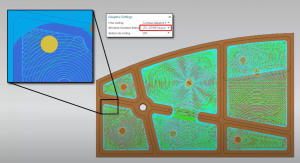

Specifying a larger value, increases the size of the smallest cuts even further. A minimum curvature radius less than 5% of the tool diameter can not be specified. Also, a minimum curvature radius greater than 50% of the tool diameter can not be used.

The minimum cut depth option is also available now. This value defines the depth of the first cut level measured from the blank geometry. Like setup distance, minimum cut depth is available when bottom up cutting is set “Between Set Levels”