- September 21, 2020

- Posted by: Sapience

- Category: Blog

No Comments

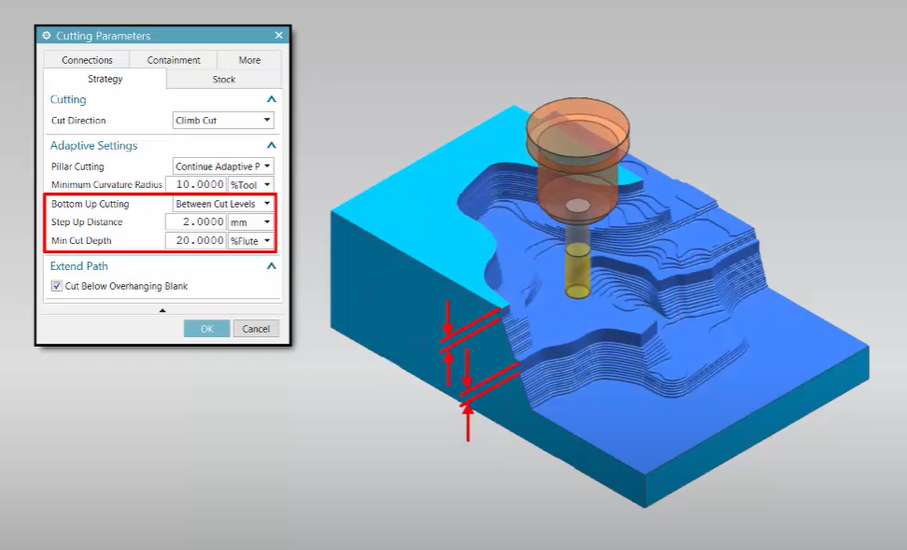

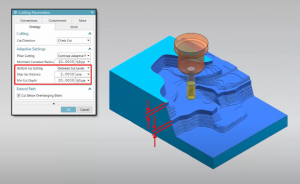

Bottom Up Cutting in Adaptive Milling can be used to control stock removal between cut levels.

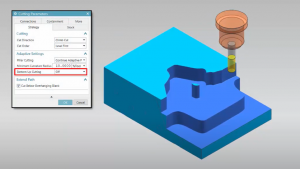

Typically, Adaptive milling establishes cut level that utilizes as much as the tool flute length as possible.

Without Bottom up cutting, it leads to excess amount of stock remaining between the levels.

With bottom up cutting, the tool path recut the walls at each cut level from the bottom up using the specified minimum cut depth.

The step up distance determines the distance between step up levels. This ensures the uncut stock left on the tapered and uncut walls in rough machining operations is minimal, consistent and evenly distributed, helping to stabilize the cutting tool performance during semi finish and finishing operations.